Plastic bottles can be seen everywhere in our day-to-day lives. Products such as water bottles, soda bottles, cooking oil, and food containers for mustard and ketchup and other food products are all made of plastic. As we know there are different types of plastics but for producing bottles that contain food or potable water, manufacturers prefer Polyethylene terephthalate which is also commonly known as PET. This material produces bottles that are lightweight, yet strong and durable. Although manufacturers may vary the process slightly based on proprietary methods, the basic method for producing bottles is universal.

Raw Materials

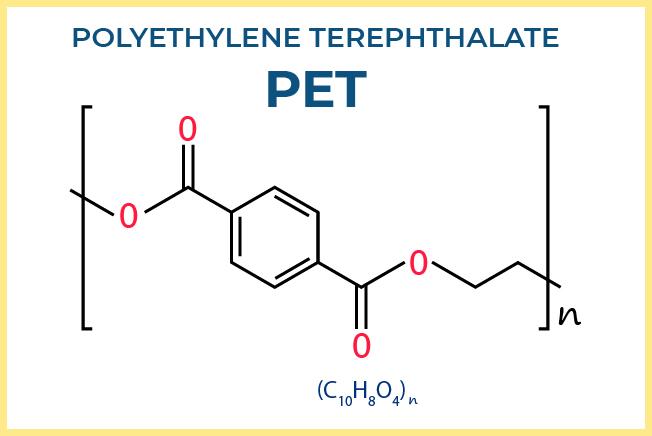

PET is a plastic resin derived from petroleum hydrocarbons. The producer creates long chains of plastic molecules through a process called polymerization and then mixes the material with several chemical compounds. They cut the resin into small pellets and send it on to the bottle manufacturer. The bottling plant mixes PET resin pellets with "regrind" -- recycled plastic that has been reduced to flakes. Plastic loses some of its physical properties when repeatedly heated, so manufacturers must limit the amount of regrind they use, typically capping this ingredient at 10% of the total mix. Unless producing clear bottles, dyes are introduced to the mix as well.

Building a Preform

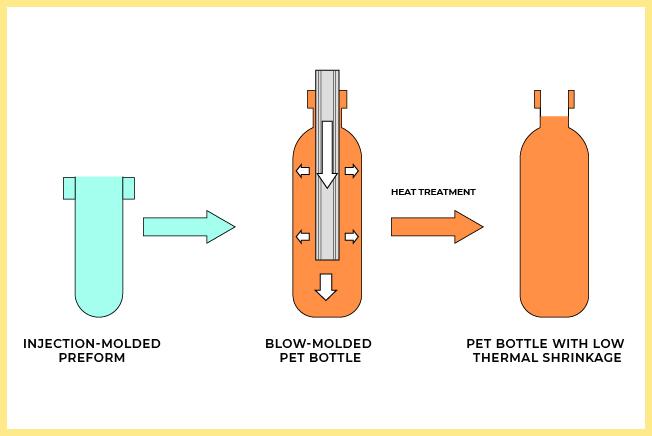

An extruder melts the PET and regrinds the mix at temperatures of about 260 degrees Celsius. A screw inside the extruder compresses the PET mix and injects the nearly molten material into molds. The mold produces a bottle preform, which is sometimes called a parison. The preform looks like a thick-walled test tube, often including the bottle's characteristic screw top. The preform cools as it travels to a machine called a blow molder, and may need to be brought back up to the manufacturer's specified temperature for that operation. If necessary, the bottle manufacturer raises the temperature of the preform in a small oven.

Stretching the Preform

The preforms enter a two-part mold that closes around it. The inside of this mold is shaped exactly like the finished bottle. Inside, a long needle pushes up through the preform, which is suspended with the screw end facing downward. The needle stretches the preform upward toward the top of the mold -- which will be the bottom of the bottle -- and simultaneously blasts enough pressurized air into the preform to force it against the sides of the mold. This stretch blow molding process must happen quickly to maintain the bottle's integrity and consistent shape. Some manufacturers weld a separate bottom piece to the bottle during blow molding, while others produce a bottom from the preform along with the rest of the bottle.

Cooling and Trimming

The bottle must be cooled almost instantly or it will lose its shape when gravity causes it to creep downward in its malleable, heated state. Some manufacturers cool the bottle by circulating cold water or liquid nitrogen through the mold, others elect to fill it with a shot of air at room temperature. The mold typically yields a clean bottle, but some flashing may occur at the bottle seams, where the two mold halves meet. If so, operators trim away the excess material and add it to the regrind. This is basically how a PET bottle is manufactured.

Compared to other plastics, PET has a high recycling rate. In India, around 1.3 Billion PET bottles are produced every day and according to the government, around 80 percent of these used bottles are collected and recycled and reused to make new PET bottles. And with the rate of consumption growth in the country, the number of production of these bottles is only going higher in the future.

Share this page